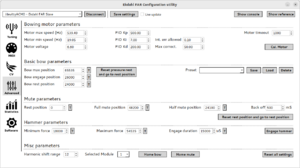

The Ekdahl FAR - Configuration utility - Advanced tab

The Advanced-tab

The Advanced-tab contains detailed parameters, a lot of these parameters are set by the Automatic calibrations, but they can be changed here either because the calibration failed for some reason, or to fine tune them and make them work even better.

Value changes are sent instantly to the instrument but are - as usual - not saved unless the Save settings-button is clicked. Any button labeled "T" is a Test-button and will set the instrumented in the associated state.

Bowing motor parameters

The first two parameters on the top left, Motor max speed and Motor min speed are somewhat special in that they cannot be changed. These two speeds are measured by clicking the Cal. Motor-button on the lower right and denotes the physical maximum speed that the bowing motor can reach, and the lowest speed that it can stably obtain while fed a constant pulse width. A few things needs to be noted here; these two speeds are to be measured without load, meaning when the bowing wheel is not touching the string. For this reason the bowing motor may not be able to reach its maximum speed depending on the amount of pressure that is applied. Furthermore the lowest speed is almost never able to be obtained with any pressure applied because of inertia. The minimum and maximum speeds are also a result of the Motor voltage, if this latter value is changed for some reason you should run the motor speed calibration again by clicking the Cal. Motor-button. The existence of these parameters are mainly for internal use by other calibration functions, the motor voltage however could be beneficial to tweak in order to obtain lower speeds for lower pitched strings.

The PID Kp, PID Ki, PID Kd, Int. err allowed and Max correct. settings are all referring to the internal PID Controller used by the Ekdahl FAR. These parameters are essentially just here for the very serious nerds who already know about PID Controllers and could be experimented with to perhaps obtain a faster and more stable response for future use. The first three settings should be self-explanatory to anyone nerdy enough to know about these things, the Int. err allowed is the integral error allowed and sets a frequency error level below which the PID decides it's "good enough" and will not force any correction (to avoid oscillations). The Max correct. stands for Maximum correction and sets the maximum frequency correction allowed per consecutive call to the PID Controller. As of this writing the PID Controller is called every 10 mS and the maximum correction is 50 Hz giving it a maximum response speed of 5000 Hz per second.

The Motor timeout value sets an automatic timeout (in mS) that occurs when a bow pressure rest-command is sent, in effect this value decides how long to wait for a new note to be sent before automatically turning off the bowing wheel. This timeout is only used when the bow control speed mode is set to automatic.

Basic bow parameters

These parameters sets the bow max-, bow engage- and bow rest positions as used by the instrument and overrides any calibrations made. See the limits-section for details.

The Reset pressure rest and go to pressure rest position-button will set the pressure rest position to 0 and put the bowing jack in that position. Basically what this does is setting the bowing jack to it's lowest possible mechanical position, this is used when needing to move the bowing jack motor to obtain better reach.

Presets: Presets are comprised of stored values of different Bow Max-, Bow engage- and Bow rest position values. The idea is that since different bowing wheels often require different settings, if changing the wheel mid-performance the user should not have to run the instrument through the pressure calibration-process but can save different values for different wheels as presets.

Mute parameters

These parameters sets the hopefully now familiar Mute rest- and Mute full mute position. See the limits-section for details.

The Back off parameter sets how long the mute is physically muting the string when it gets a mute full mute command, before it "backs off" to the mute rest position. The reason to use automatic backing off is quite simple; if the mute is touching the string and a new event is sent either to the hammer or the bowing wheel, the amount of time it takes for the mute to physically move away from the string will more often than not create a muffled attack. By backing off the mute away from the string well before any sound is produced, this is avoided.

The Reset rest position and go to rest position effectively sets the Mute rest position to 0 and puts the mute in that position, i.e. the physical minimum that the mute can reach. This is used before physically moving the Mute motor to obtain better reach after changing to a differently thick string.

Hammer parameters

The Minimum- and Maximum force parameters are explained in the limits-section.

The Engage duration parameter sets how long the the pulse that triggers the solenoid is. Changing this value can have impact on the sound of the hammer but will also affect the Minimum- and Maximum force able to be used.

The Engage hammer-button engages the hammer at full force.

Misc parameters

The Harmonic shift range sets how many notes (1/12th of an octave) of range the harmonic shift-command has, this affects the default behavior of the MIDI pitch bend message and the Harmonic shift-knob on the control box.

The Select module-drop-down is reserved for future use.

The Home bow- and Home mute-buttons will reset the bowing jack and mute positions and can be used if the Ekdahl FAR looses track of them due to over-power. The homing is done automatically every time the Ekdahl FAR is turned on.

The Reset all settings-button will revert all settings in the Ekdahl FAR to factory settings, this includes all MIDI- and CV mappings.