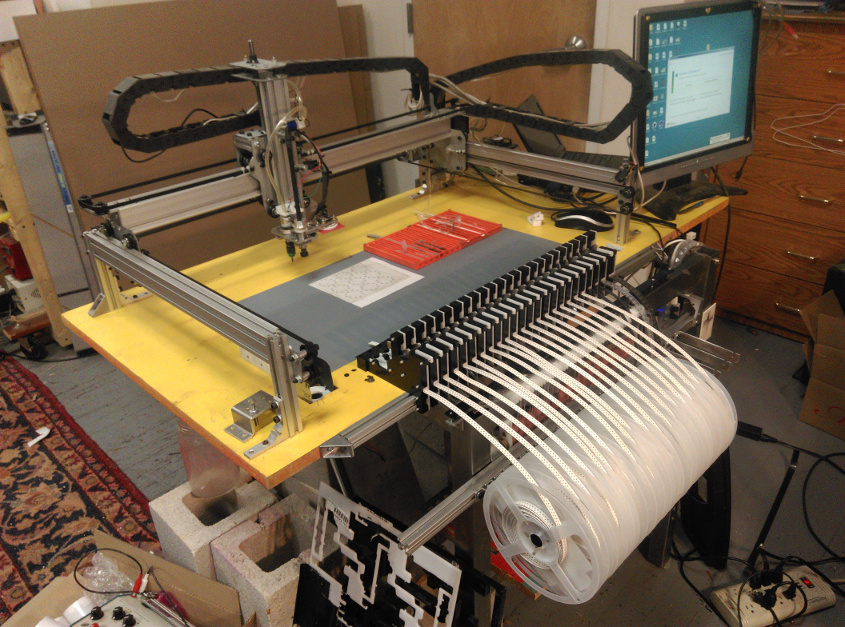

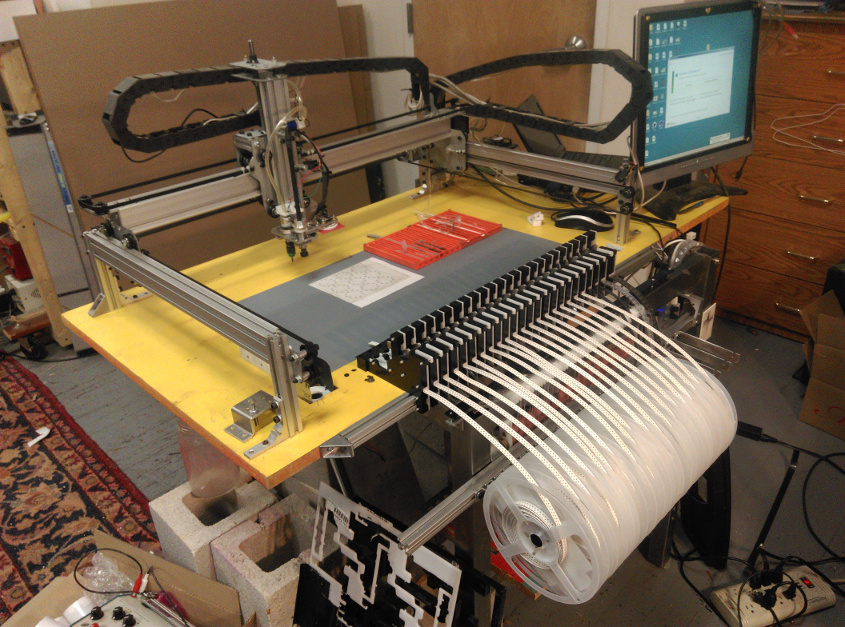

Pick-and-place machine

Simply put, a pick-and-place machine is a CNC robot that picks stuff up from one location, and places them in another. My pick-and-place machine is used to

pick up components from reels and automatically place them on circuit boards, this is a huge time saver over manually placing all the components and is in

fact how all factory made circuit boards are done.

After looking around at various options i decided to go with a

LitePlacer kit as it seemed to be the best option for the money.

I was looking at commercial machines but most of the new ones that were in my price range were too simple and i felt that my ability to expand on a ready-made unit

was limited. There are a bunch of used old machines out there, but i felt that the maintenance required and the size and weight of them were prohibitive.

The liteplacer is supposed to be a prototyping machine, since i wanted a production machine i've done a serious of modifications / upgrades to my unit in order

to get it up to snuff. These things will be listed here.

Among the upgrades necessary i've had to modify the software a bunch, you can find my fork of the liteplacer software on

github. My company normally only runs linux software, this in fact being the only software requiring

a proprietary operating system. For this reason i will try and migrate to using

OpenPNP as soon as i feel that it has matured

to a stage where i can use it in a production environment.

One of the most important upgrades i have done to my machine is the addition of Tape Feeders, please go

here for more info.